Heavy Duty & Reliable Trolley Wheels for Every Application

Discover Muvall’s premium range of trolley wheels engineered for durability, load-bearing performance, and effortless movement. Whether you need small trolley wheels for furniture or heavy-duty industrial trolley wheels for material handling, our precision-built solutions ensure smooth mobility, long service life, and dependable performance in every environment.

About Trolley Wheels

At Muvall, we design and manufacture high-performance trolley wheels that deliver strength, stability, and seamless motion across diverse industrial and commercial applications. Our wheels are built using advanced materials — rubber, nylon, polyurethane, steel, UHMWPE, and engineering plastics — and tested for dynamic load capacity as per IS 22878:2004 standards. Each trolley wheel features precision ball bearings for friction-free rolling, robust construction for heavy loads, and a refined finish for professional appearance. From small 2-inch and 3-inch wheels for compact trolleys to 10-inch heavy-duty wheels for industrial carts and up to 15-inch pneumatic rubber wheels for wheelbarrows, every Muvall product embodies quality, reliability, and decades of manufacturing expertise.

Explore Our Industrial Trolley Wheels Categories

Discover a complete range of Trolley wheels engineered for light, medium, heavy-duty, and specialized industrial applications. Designed for durability, load performance, and smooth mobility across industries.

Light Duty Castor Wheels

Perfect for light applications with loads up to 100kg per wheel. Ideal for office furniture, light trolleys, and equipment.

View Product

Medium Duty Castor Wheels

Designed for medium load applications up to 500kg per wheel. Suitable for industrial trolleys and material handling equipment.

View Product

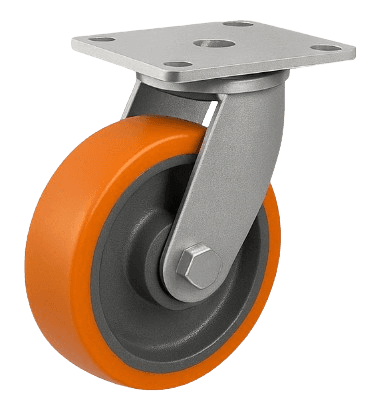

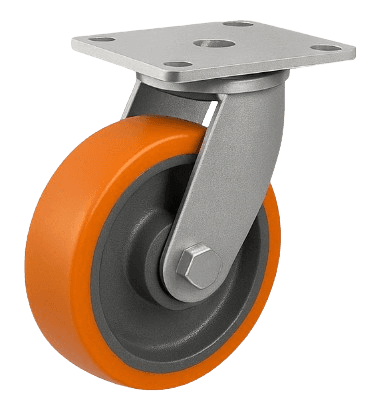

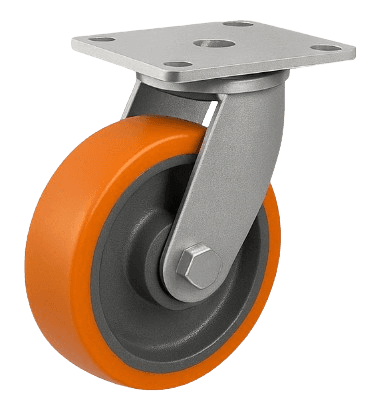

Heavy Duty Castor Wheels

Built for heavy industrial applications up to 2000kg per wheel. Perfect for heavy machinery and industrial equipment.

View Product

Special Application Wheels

Customized solutions for specific environments including medical, food-grade, ESD, and high-temperature applications.

View ProductKey Features of Trolley Wheels

Premium Engineering Features

Premium Engineering Features

Choose the Material Wise Trolley Wheels

Rubber Trolley Wheels

Available types: Thermoplastic Rubber (TPR), Pneumatic, Elastic, Solid, Industrial

Ideal for: ideal for indoor and outdoor environments.

View ProductNylon Trolley Wheels

Available types: Injection Moulded Nylon, Cast Nylon

Ideal for: Offer high load capacity, low rolling resistance, and resistance to chemicals, moisture, and abrasion. Perfect for manufacturing, logistics, and heavy-duty handling.

View ProductPolyurethane (PU) Trolley Wheels

Available types: Multiple treads and cores (PP, Nylon, CI)

Ideal for: Combines toughness and elasticity to deliver longer life, better floor protection, and reduced operator fatigue.

View ProductPVC / Polypropylene Trolley Wheels

Available types: PVC, Polypropylene (PP)

Ideal for: Lightweight, corrosion-resistant, and economical. Best suited for light to medium-duty trolleys and indoor commercial applications.

View ProductCI / Metal Trolley Wheels

Available types: Cast Iron (CI), Metal

Ideal for: Made for extreme load conditions and rugged surfaces. Widely used in foundries, fabrication units, and heavy engineering applications.

View ProductUHMWPE Trolley Wheels

Available types: Ultra-High Molecular Weight Polyethylene

Ideal for: Provide high wear resistance, excellent load-bearing capacity, and smooth rolling even in chemical or wet environments. Ideal for food processing and cleanroom applications.

View ProductRubber Trolley Wheels

Available types: Thermoplastic Rubber (TPR), Pneumatic, Elastic, Solid, Industrial

Ideal for: ideal for indoor and outdoor environments.

View ProductNylon Trolley Wheels

Available types: Injection Moulded Nylon, Cast Nylon

Ideal for: Offer high load capacity, low rolling resistance, and resistance to chemicals, moisture, and abrasion. Perfect for manufacturing, logistics, and heavy-duty handling.

View ProductPolyurethane (PU) Trolley Wheels

Available types: Multiple treads and cores (PP, Nylon, CI)

Ideal for: Combines toughness and elasticity to deliver longer life, better floor protection, and reduced operator fatigue.

View ProductPVC / Polypropylene Trolley Wheels

Available types: PVC, Polypropylene (PP)

Ideal for: Lightweight, corrosion-resistant, and economical. Best suited for light to medium-duty trolleys and indoor commercial applications.

View ProductCI / Metal Trolley Wheels

Available types: Cast Iron (CI), Metal

Ideal for: Made for extreme load conditions and rugged surfaces. Widely used in foundries, fabrication units, and heavy engineering applications.

View ProductUHMWPE Trolley Wheels

Available types: Ultra-High Molecular Weight Polyethylene

Ideal for: Provide high wear resistance, excellent load-bearing capacity, and smooth rolling even in chemical or wet environments. Ideal for food processing and cleanroom applications.

View ProductEach material is selected for its mechanical strength, temperature tolerance, and wear resistance, ensuring optimal performance and longevity in your specific operating environment.

Trolley Wheels Applications & Industries wise

Muvall trolley wheels are designed to perform reliably across industries.

Manufacturing & Engineering

Machine trolleys, tool carts, and material handling systems.

Recommended: PU, Cast Nylon, and Phenolic castors

Load Capacity: Up to 2 tons per wheel

Warehousing & Logistics

Pallet trolleys, storage units, and platform trucks.

Recommended: PU, Nylon, and PP castors

Features: Precision ball bearings for effortless rolling

Automotive Workshops

Engine stands, maintenance trolleys, and parts carriers.

Recommended: PU, Elastic Rubber, and Cast PU

Benefits: Oil and solvent resistance

Hospitals & Healthcare

Medical trolleys, stretchers, and diagnostic carts.

Recommended: PU, Cast Nylon, and Phenolic castors

Load Capacity: Up to 2 tons per wheel

Retail & Institutional

Display stands, store trolleys, and cafeteria carts.

Recommended: PU, Nylon, and PP castors

Features: Precision ball bearings for effortless rolling

Construction & Outdoor Use

Scaffolding trolleys, wheelbarrows, and cable carriers.

Recommended: PU, Elastic Rubber, and Cast PU

Benefits: Oil and solvent resistance

Why Choose Muvall Trolley Wheels

- Tested & Certified: Dynamic load testing as per IS 22878:2004 standards.

- High Load Capacity: Options ranging from 30 kg to 2 tons per wheel.

- Smooth Performance: Precision double ball bearings ensure effortless rolling and low resistance.

- Material Versatility: Available in rubber, nylon, PU, UHMWPE, PVC, and metal variants.

- Global-Grade Raw Materials: Sourced from trusted international suppliers.

- Warranty Assurance: Products backed by a warranty against manufacturing defects.

How to Choose the Trolley Wheels

Selecting the right trolley wheel enhances safety, mobility, and equipment lifespan

Determine Load Requirements

Calculate weight per wheel using total load, equipment weight, number of wheels, and a safety factor based on speed, flooring, and load type.

Choose Wheel Material

Select material according to floor type, ergonomics, chemical/moisture exposure, and temperature resistance requirements.

Select Castor Type & Mounting

Choose castor type (pressed steel, forged steel, stainless steel) for strength and environment suitability.

Check Mounting Type

Swivel for maneuverability, fixed for straight-line stability, and brake castors for safety in stationary use.

Determine Load Requirements

Calculate weight per wheel using total load, equipment weight, number of wheels, and a safety factor based on speed, flooring, and load type.

Choose Wheel Material

Select material according to floor type, ergonomics, chemical/moisture exposure, and temperature resistance requirements.

Select Castor Type & Mounting

Choose castor type (pressed steel, forged steel, stainless steel) for strength and environment suitability.

Check Mounting Type

Swivel for maneuverability, fixed for straight-line stability, and brake castors for safety in stationary use.

Maintenance Tips for Trolley Wheels

Inspect bearings, axles, and fittings periodically.

Keep wheels free from debris, moisture, and corrosive chemicals.

Lubricate moving parts regularly for smooth rolling.

Replace worn or damaged treads promptly to prevent operational strain.

Regular Care for Long-lasting Performance

Request a Quote

Do you have questions or inquiries about industrial castors and wheels? Get in touch with Muvall, your leading castor wheel manufacturer and exporter in India.

Load Capacity Calculator

Use our Load Capacity Calculator to determine the ideal Trolley wheel specification based on the load, floor type, usage, and speed.

Our Clients

Industries Benefiting from Our Caster Wheels

We’re proud to be the trusted caster wheels partner for leading businesses across industries.

Our Testimonials

Anand - Owner

Harsha Enterprise, Bangalore

Working with Muvall Castor & Wheels has been a delight! As a supplier, they are incredibly reliable and always ensure timely delivery of top-quality caster wheels. Their professionalism and dedication to customer satisfaction are commendable. Looking forward to continuing our successful partnership!

Need durable trolley wheels for your business?

Fill out our enquiry form or talk to our experts for the perfect mobility solution.

Frequently Asked Questions

Find answers to some of the most common questions about our products, shipping, and returns.